CENTER FOR

ADVANCED MANUFACTURING

KIHOMAC’s Center for Advanced Manufacturing serves as the workspace for almost two-thirds of our

employee base.

Center for

Advanced manufacturing

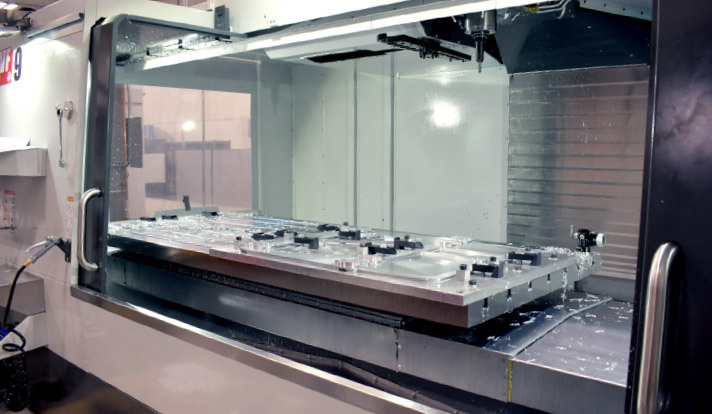

CNC Machines

- Haas UMC 1000SS 5-Axis Mill

- Haas 750SS 5-Axis Mills (3)

- Haas VF-9/40 3-Axis Mills (2)

- Haas ST35Y CNV Lathe

- Haas VR 11B 5-Axis Mill

- Haas UMC 750 5-Axis Mill

- Thermwood CNC 5-Axis Dry Mill

- Flow Mach 2 Waterjet

- OKUMA MILLAC-853PF-5x

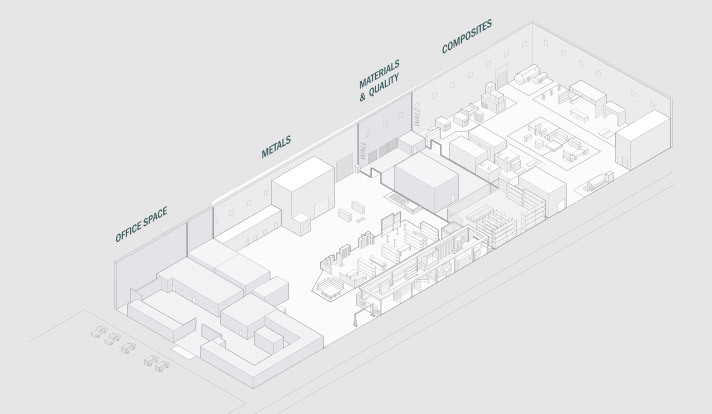

Controlled environments

- Clean Rooms, ISO Class 8 (2)

- Paint Booth (14’ x 30’)

- Sanding Booths (2)

Heat Treatment

- Ovens (2): Class A 288 ft2 – 500°F

- Autoclaves (2): 8’ x 14’ (1) and 3’ x 12’ (1) 450°F – N2 150 PSI

Additional Equipment

- 300-Ton Hydraulic Press

- Manual Lathe

- Filament Winding Machine

- Eastman Cutting Tables (2)

- Builder Extreme 1000 3D Printer

KIHOMAC’s Primary

Manufacturing Location

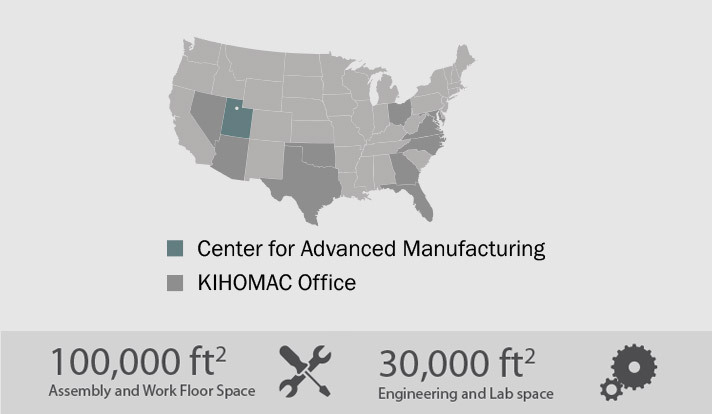

KIHOMAC’s Center for Advanced Manufacturing serves as the workspace for almost two-thirds of our

employee base. Boasting an expansive 100,000 ft2 work floor, 30,000 ft2 of engineering and laboratory space, and equipped with state-of-the-art machinery, we are able to provide a variety of complex manufacturing solutions. Our manufacturing capabilities include advanced composite materials, wiring harness production, and complex metal products. Our dedication to excellence and focus on meeting our customer’s

needs within tight deadlines has earned us an outstanding reputation as a small business with

extraordinary capabilities.